Compact Manual Clay Brick Machine

A comprehensive brick manufacturing solution suitable for rural construction and small business ventures, delivering efficient, high-quality production of clay bricks through advanced hydraulic pressing technology.

Product Overview

The Electric Clay Brick Machine revolutionizes brick-making by combining modern technology with robust engineering to deliver consistent, durable bricks. Featuring a powerful Hydraulic Clay Brick Press, this machine ensures precise compaction for excellent density and strength. The energy-efficient electric motor provides reliable operation with reduced environmental impact, while the intuitive control panel allows for easy parameter adjustment and versatile brick production.

Key Features

- High-performance electric operation for consistent brick production

- Energy-efficient design reduces power consumption and operational costs

- Durable construction ensuring long-lasting machine life

- Capable of producing various sizes and shapes of clay bricks

- User-friendly interface for easy operation and control

- Compact, space-saving design suitable for various production scales

- Fast production rate to meet high demand requirements

- Environmentally friendly with low emissions and waste production

- Robust motor and components ensuring reliable performance

Technical Specifications

| Machine Type |

Semi Automatic Brick Maker |

| Material |

Clay |

| Function |

Clay Brick Forming Machine |

| Output Capacity |

Up to 10,000 bricks per day |

| Power Source |

Electric / Diesel |

| Energy Efficiency |

Energy Efficient Brick Maker with low power consumption |

| Brick Size |

Standard and custom sizes available |

| Operation |

Semi automatic with manual feeding |

| Weight |

Approx. 800 kg |

| Dimensions |

2000 mm x 1200 mm x 1500 mm |

Applications

The Halstec JKY60 Electric Clay Brick Machine is ideal for construction companies, real estate developers, and brick manufacturers requiring efficient, sustainable production. Suitable for both rural and urban sites, its portability and energy-saving technology make it perfect for various construction projects, infrastructure development, and remote building applications.

Support & Services

Comprehensive technical support including installation guidance, operation training, routine maintenance, troubleshooting, spare parts replacement, and on-site inspection services to ensure optimal performance and minimal downtime.

Packing & Shipping

Machines are securely packaged with protective materials and sturdy wooden crates. Shipping options include sea, air, and land transportation with detailed documentation provided for tracking and verification.

Frequently Asked Questions

What is the brand and model number of the clay brick making machine?

The clay brick making machine is from the brand Halstec, and the model number is JKY60.

What certifications does the Halstec JKY60 clay brick making machine have?

The machine is certified with CE and ISO certifications, ensuring quality and safety standards.

What is the minimum order quantity and price range?

Minimum order quantity is 1 set, with prices ranging from USD 40,000 to 60,000 per set.

What payment terms are accepted?

Payment terms include T/T (Telegraphic Transfer), LC (Letter of Credit), or negotiation.

What is the supply ability and delivery time?

Halstec can supply 5 sets per month, with delivery within 30 days after advanced payment.

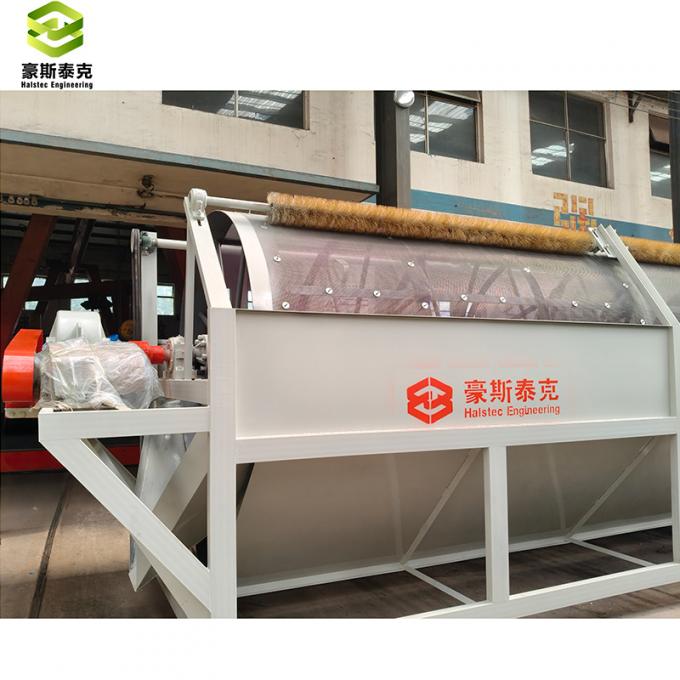

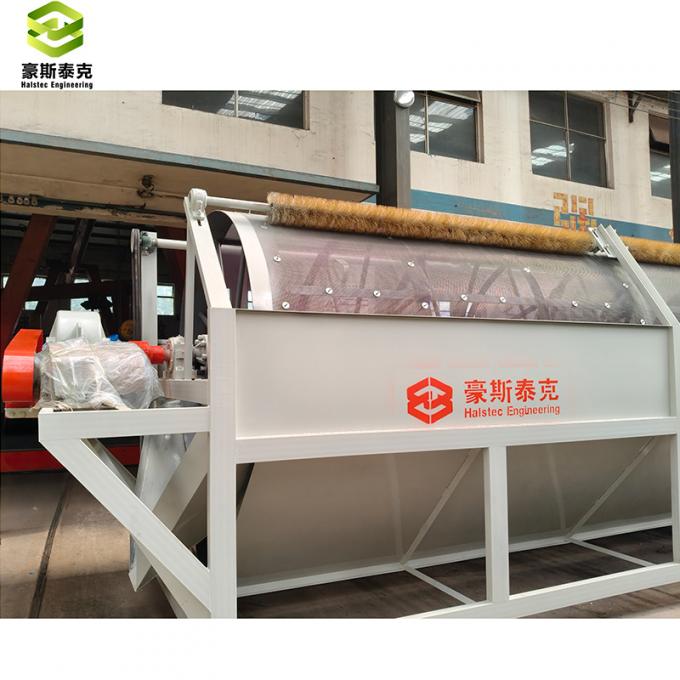

Product Images

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!